Clubsport Carpet

DIY Track Car Interior – Installing a Custom Clubsport Carpet

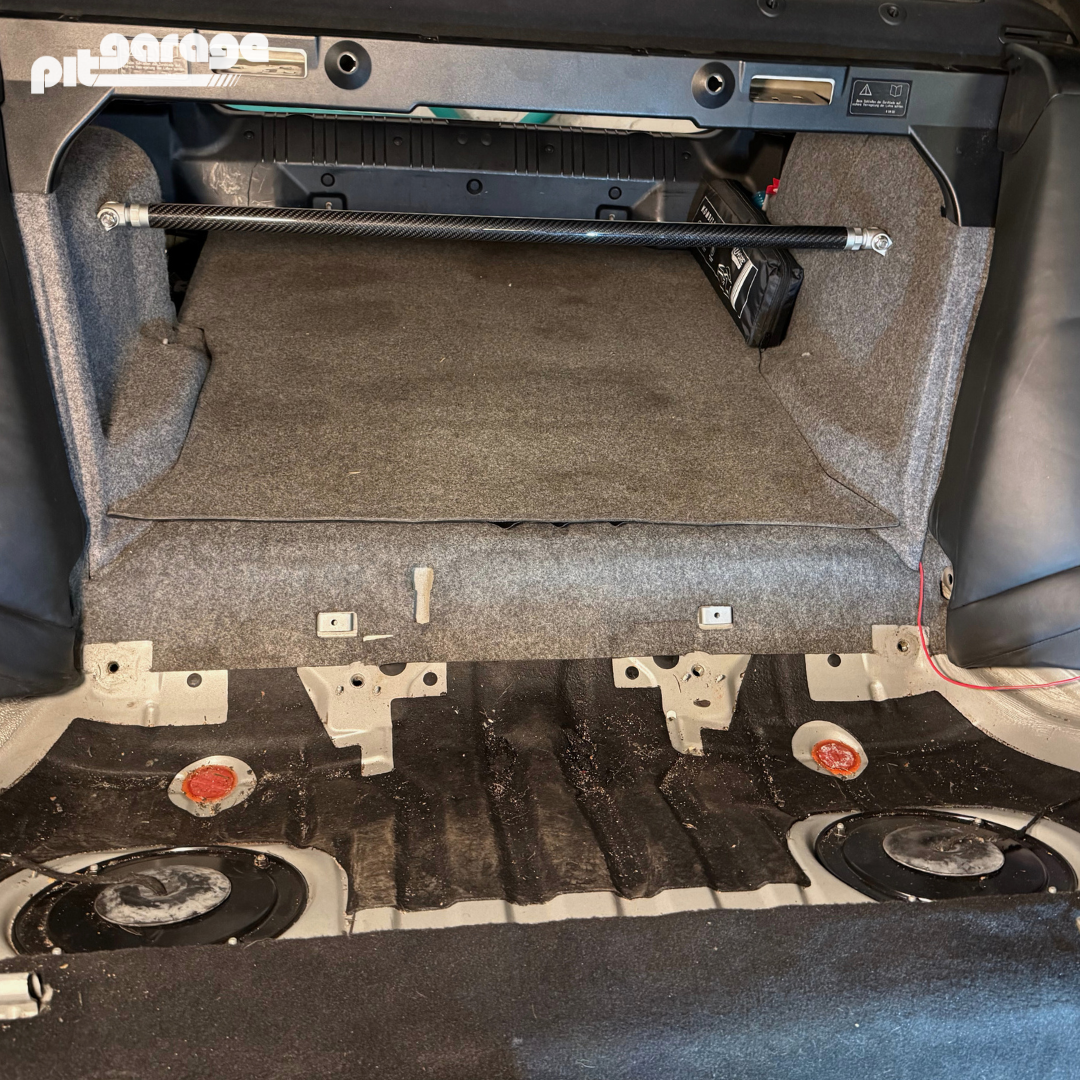

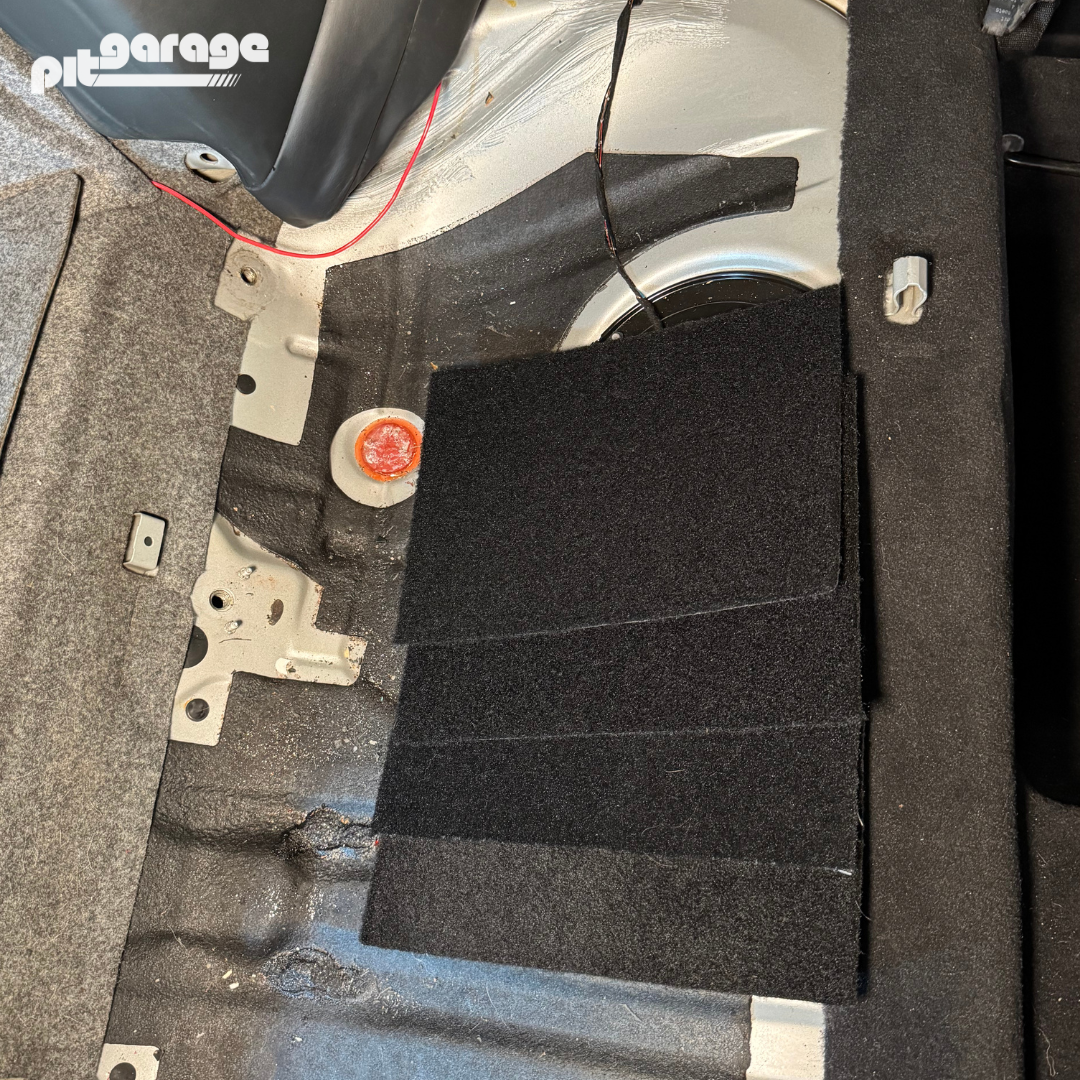

When I removed the rear seats from my E46 M3, I immediately noticed how unfinished the area looked. It was the only part of the interior without carpeting or any kind of trim, making it stand out in a way I didn’t like. Since I’ll eventually strip the entire interior for maximum weight savings, I could have just left it bare. But I prefer a clean and aesthetically pleasing look, even in a track-focused build. So, I decided to create a custom carpet to cover the rear seat area. While I was at it, I also replaced the trunk carpet, which had seen better days. I extended the new carpet seamlessly from the trunk all the way to the rear seat area for a consistent, OEM-like finish.

You can do this yourself easily and affordably with just a few tools and some basic DIY skills.

- Choosing the Right Carpet for a DIY Track Car Interior

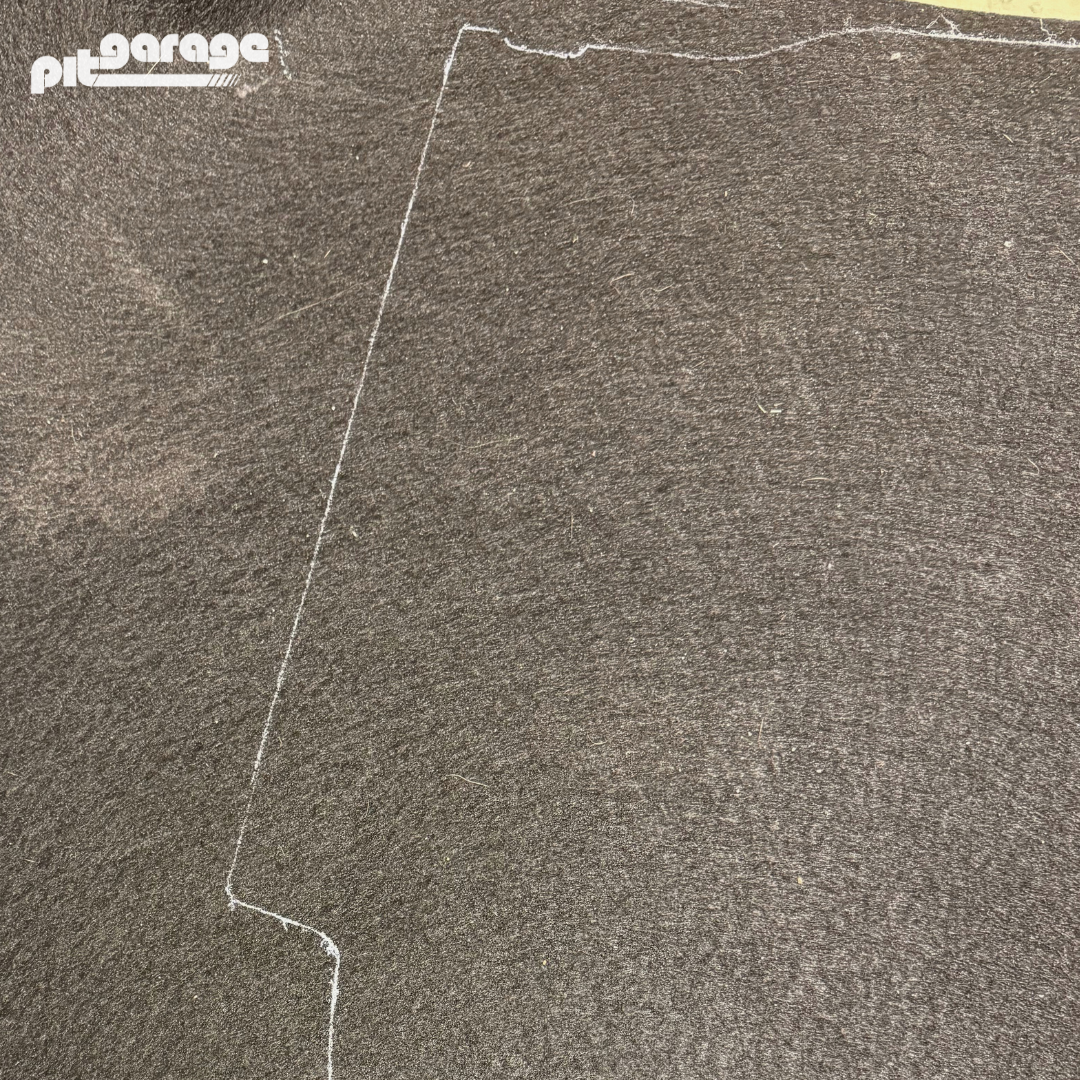

- Creating a Template for Your Clubsport Carpet Install

- Cutting the Carpet for a Perfect Fit in Your E46 M3

Final Installation & Adjustments for a Clean DIY Interior Look

Tools / Parts needed

- Sharp Scissors or Utility Knife

- Tape Measure

- Tape

- Marker

- Thick Paper or Cardboard

- Carpet 1,5 m x 2 m (5 ft x 6,5 ft)

1. Choosing the Right Carpet

1.1 Initial Situation: After removing the rear seats, the exposed metal surface didn’t look great. Since I prefer a clean and aesthetic look, I decided to cover the area with carpet. The original trunk carpet was also old and worn out, so I chose to extend the new carpet from the trunk all the way to the rear seat area.

1.2 Measuring the Area: To determine how much carpet was needed, I measured from the trunk edge to the rear seat area and across the width of the rear seat. It’s important to follow the seat’s contours when measuring to avoid inaccurate dimensions. The minimum required carpet size is 1.7 m x 1.4 m (5.58 ft x 4.59 ft).

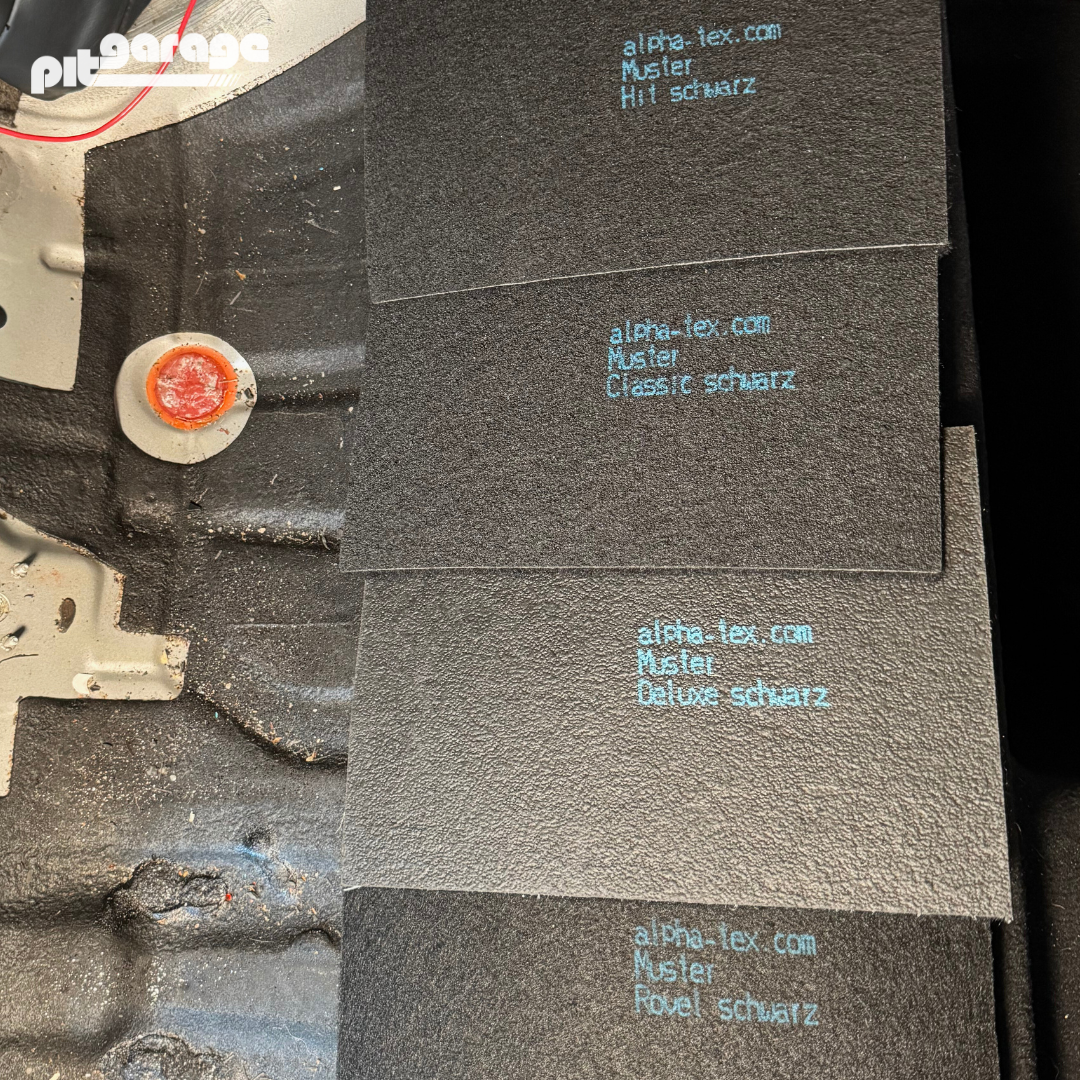

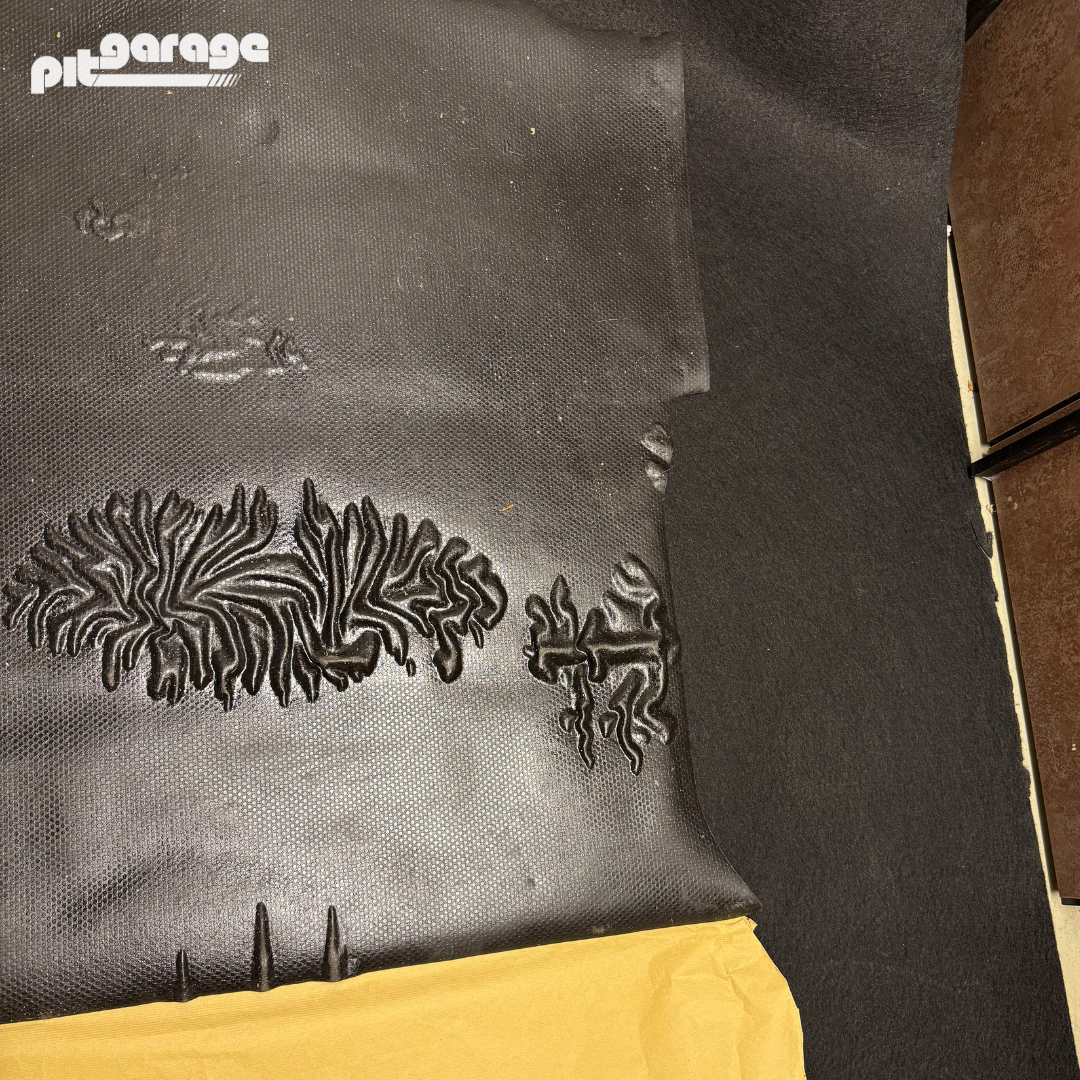

1.4 Choosing the Right Carpet: After reviewing the samples, I chose “Rovel Black” because it had the best black tone and was the thinnest and lightest option. This makes installation easier and helps keep the weight down while ensuring the carpet conforms well to the car’s interior. I ordered a 1.5 m x 2 m (4.92 ft x 6.56 ft) piece from Alpha-Tex to have some extra material for adjustments.